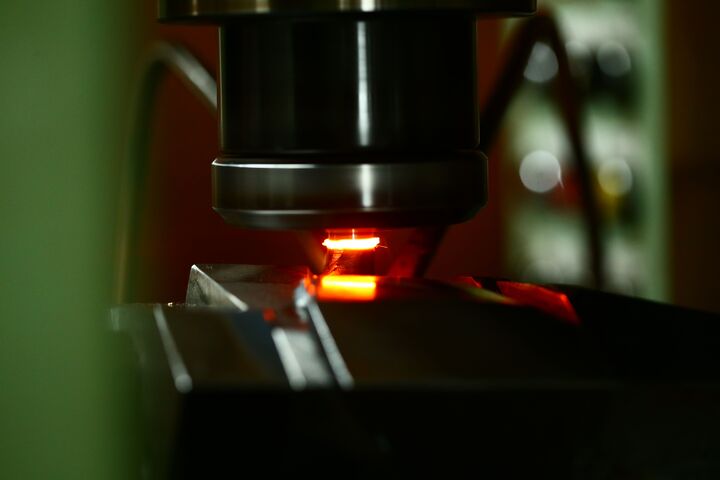

Forging

Miura-san believed the manufacturing process of forging irons was fundamentally flawed. So, he changed it. This resulted in a revolutionary new technique that elevated Miura irons to the highest industry standards with the tightest tolerances.

Your Privacy Choices

Your Privacy Choices